Flexi Weld

Robotic Welding Station, Featuring CoBot Arm, High Specification Pulse Mig Welding Set, Black Nitrile Welding Table Complete with Clamping System

Flexi Tend Max

Machine Tending Cell, Complete with On-Arm Vision, Component Blow-Off Station and Twin Conveyors

Automated Chassis Welding Cell – Complete Turn Key Solution

Second Cell for Poland

First system was so successful, they ordered another identical system

Another two powered end changer systems for Bulgaria

A pair of identical cells destined for Bulgaria ready for dismantling and shipping Each with: Fanuc robots, Lincoln MIG welders, Binzel torches & cleaning stations and tilt beds

Another 5 Robot Cell Installation

Installing 5 reconditioned Fanuc R2000i robots to existing customer presses This will be our second automated line manufacture wheelbarrow pans in West Midlands Production Video Found Here

Installation of twin robot seat welding cell

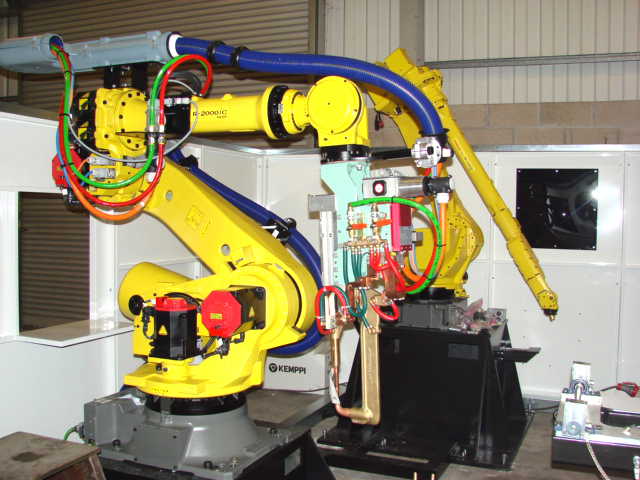

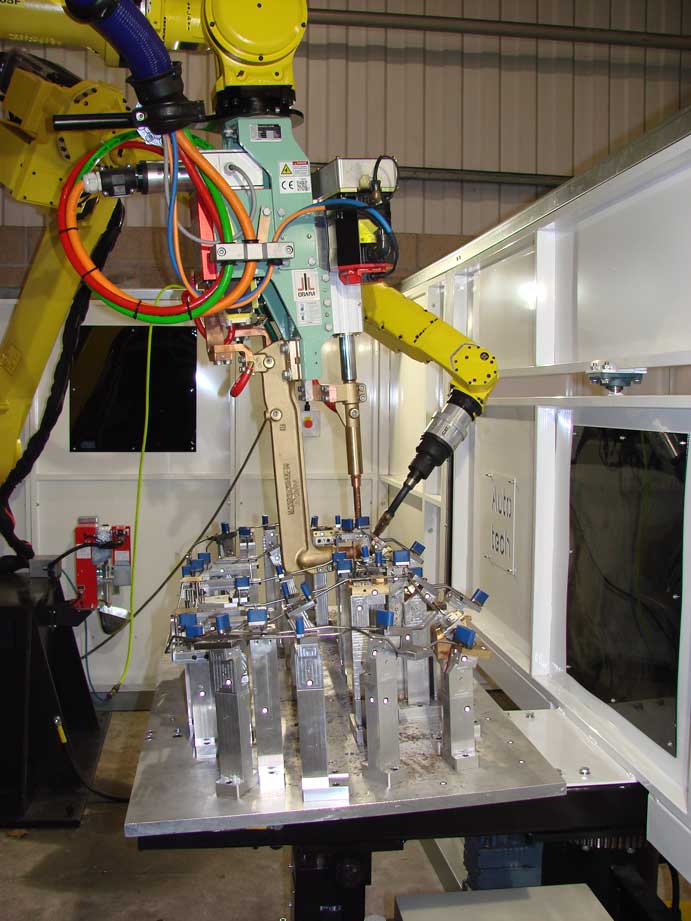

Final installation in Poland – March 2018 Starting production Fanuc R2000iC complete with 7th axis control Obara axis controlled servo gun with robot controlled tip dresser and water chiller Fanuc M710iC very long reach MIG welding robot Kemppi A7 pulsed welding equipment Loading area with table tilted Complete frame welded in under 2 […]

Powered End Changer System

Reconditioned inverter controlled powered end changer system Fanuc ArcMate 100iB Model RJ3iB with coloured teach pendant Water cooled Kemppi Pro4000, 520R MC function panel Thielmann torch cleaning station Dinze torch assembly Fully enclosed canopy Screening in Poppy Red Full 12 months warranty Ready for immediate dispatch

Testing Double Manipulator System Prior to Dispatch

Another bespoke system for one of our longstanding UK customers Final testing of the complete system including the Fanuc Robot with 2 external axis, Fronius Pulsed Welding equipment and torch cleaning station Video of walk around can be seen here: youtu.be/IE7dIKAyP1k

Reconditioned Fanuc Robot’s

ARC Mate 100i & M6i Arm’s Models RJ2, RJ3, RJ3iB & R30iA 6 axes of motion, all braked Absolute encoder positioning +/- 0.1mm repeatability Brushless AC servo motors with direct drive Arc welding software